Amrita Chakraborty: Organic ReRAMS can improve memory devices, protect environment

The following story was written in December 2021 by Jamie Ingle in ENGL 4824: Science Writing as part of a collaboration between the English department and the Center for Communicating Science.

Technology trends come and go, but what happens to our electronics once they are no longer the latest fad? Amrita Chakraborty is trying to combat the negative impact technology has on the environment.

Chakraborty, a fifth-year Ph.D. student from India studying nanoscience at Virginia Tech's Department of Electrical Engineering, is working on two projects concerning memory devices, specifically resistive random-access memory devices, or ReRAM. Memory devices are used in cellphones, computers, smartwatches, and more—all the technology we rely upon in our daily lives.

ReRAMs are different from regular random-access memory (RAM) devices because they are nonvolatile and offer different resistance levels when current runs through them. The different resistance levels allow the ReRAM device to store memory even when the device is removed from a power source.

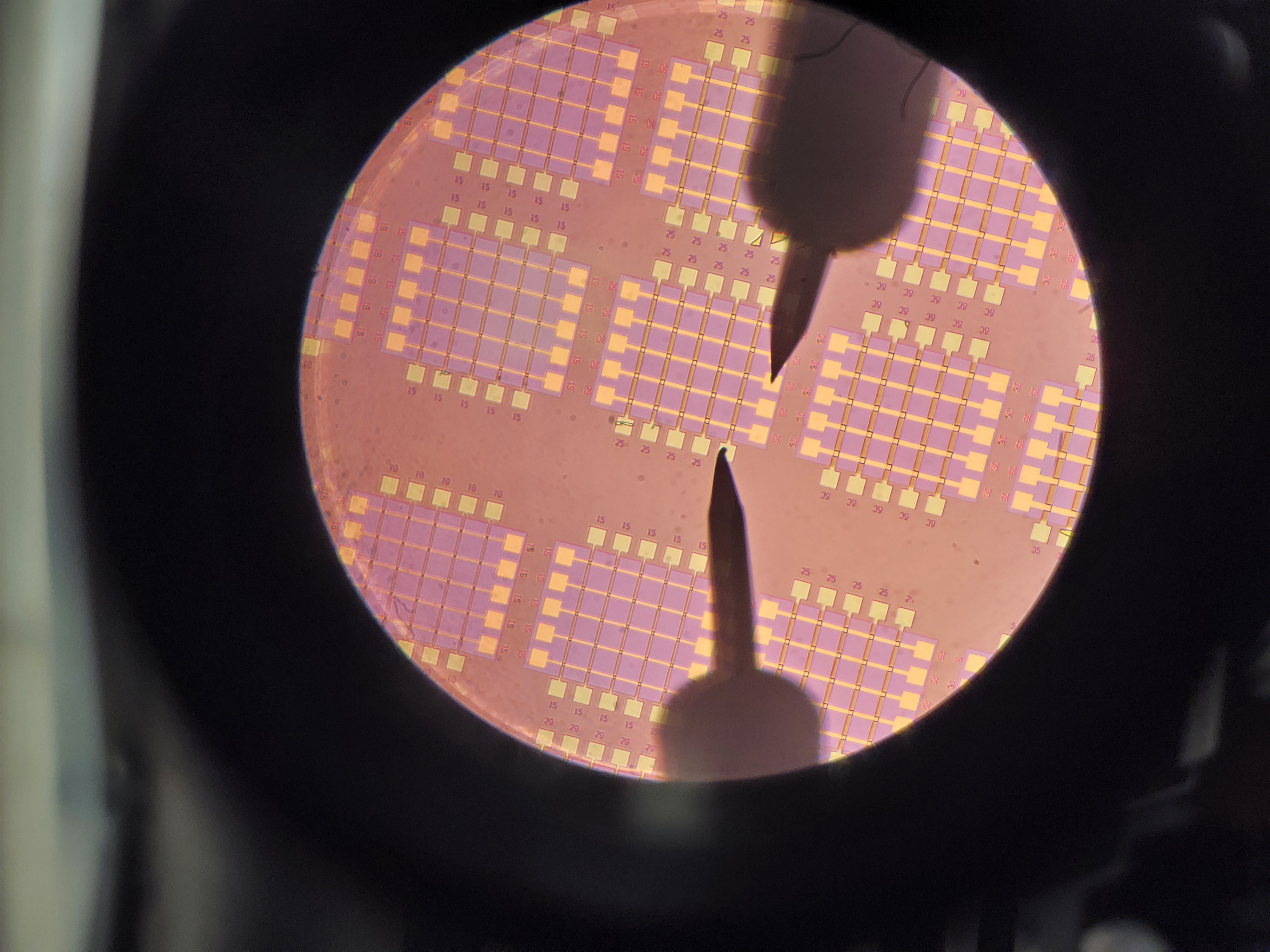

Typically, volatile memory devices have a shorter lifetime and worse performance than nonvolatile memory devices, but a ReRAM made of completely organic material may prove different. Chakraborty works with non-organic crossbar ReRAMs, which are made of layers of platinum, tantalum oxide insulation, and copper. She is also introducing organic materials that are more lightweight and have a lighter carbon footprint than other traditionally used options. For Chakraborty, this means testing different nanoscale materials to find just the right one. The organic ReRAMs she is working on will be used in green electronics. They need to be flexible and resistant to environmental conditions and to decomposition over time.

Because the substances needed for these ReRAMs are made of such fine particles, working with them can be frustrating and costly. Chakraborty recounts a failed attempt to study a substance that was expensive and wasteful. She then identified a substance known as PEDOT:PSS. This substance can potentially become an organic replacement for the copper bars typically found in ReRAMs. The substance is made of tiny fibers that can be dissolved in water, processed, and spread across the silicon layer of the device.

Since silicon is a hydrophobic (water-resisting) substance, Chakraborty says, it can be challenging to get the PEDOT:PSS mixture spread evenly across the silicon. However, once an even spread is achieved, this substance can lengthen the lifespan of the ReRAM because it is more efficient and can resist gradual wear and tear. This project is still in the preliminary stages, but Chakraborty has seen some promising results.

In another project, Chakraborty is adding a pure carbon atomic monolayer, known as graphene, to the ReRAM. Just a one-atom-thick layer of this substance renders the ReRAM heat resistant. Graphene is known to have the highest thermal conductivity of all materials known, tenfold higher thermal conductivity than the best metals such as copper or silver. These additions will make ReRAMs much more reliable and environmentally friendly.

When she isn't advancing her own research, Chakraborty is leading the research for other students. During her education in India, she received a double undergraduate degree in physics and engineering, as well as a master’s degree in engineering, which served as an entry point for her Ph.D. research. Her mentor in India pushed her to pursue an education in the United States.

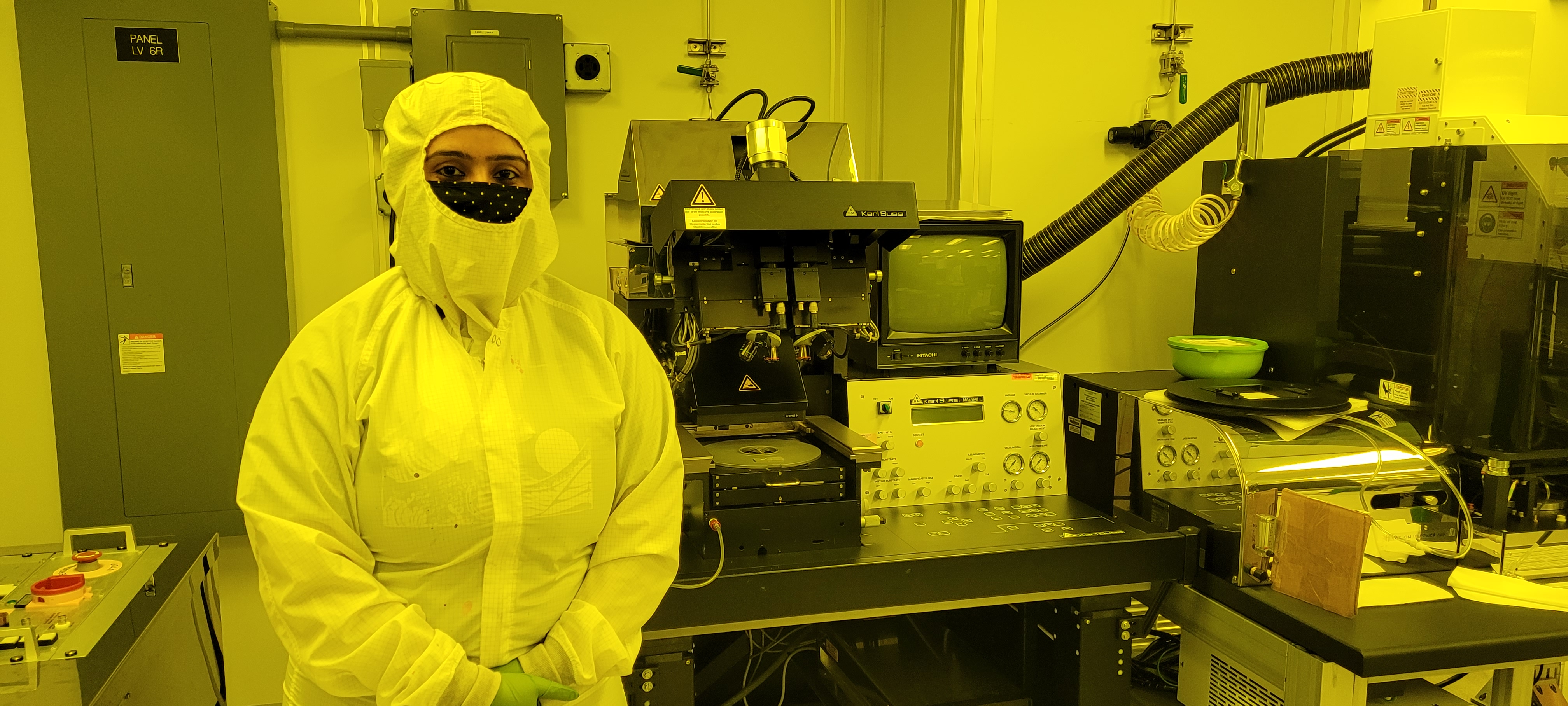

Chakraborty's program at VT, which started in 2016, splits her time between her research and aiding undergraduate research as a graduate teaching assistant (GTA). Her GTA responsibilities require her to lead a group of six students through problems posed by industry or subject-matter experts to develop better products. Chakraborty trains and oversees the lab work of these students.

Luckily for Chakraborty, her GTA research is very similar to her personal research: "My research and the GTA work I am doing—it is so closely related right now, I think the lines are blurred somewhere," she says.

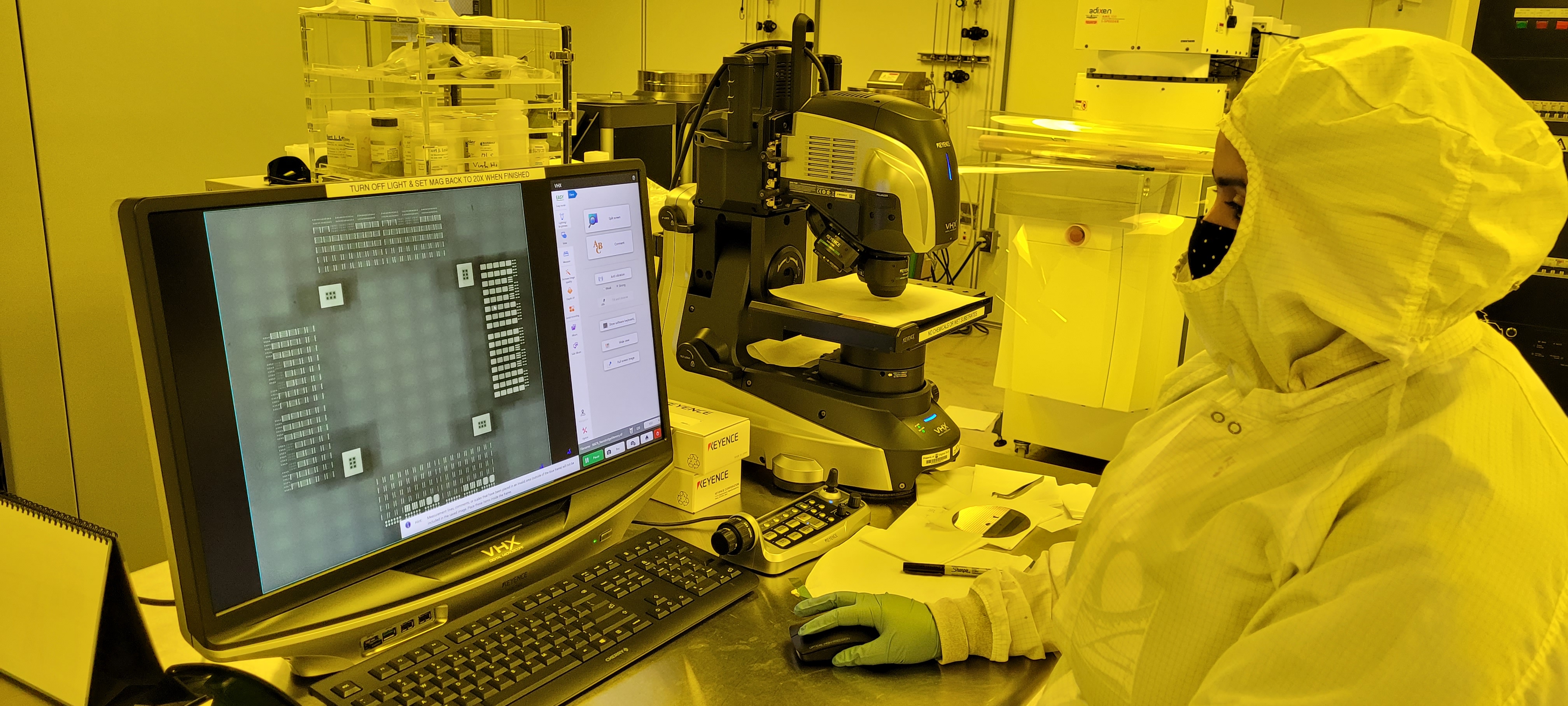

Every minute in the cleanroom is important to her, as she needs to control the number of particles in the atmosphere so that they don’t contaminate her samples—and there is small margin for error. COVID-19 restrictions made time with lab space and equipment harder to schedule, as the number of people in various rooms was limited, and lab sessions were precious and rare, she says.

"I think we all were at a mental state if something doesn't work according to our plans anymore, then we're like, okay, this is the end. Everything is going to end," Chakraborty says as she recounts issues with a malfunctioning lab machine. Her personal research days are at least 5 to 6 hours in the lab, with lab work stretching sometimes to 10 hours.

But the stress is worth it. Chakraborty hopes eventually to see organic ReRAMs available in memory devices for the general public. She also hopes to see a greater understanding of technology among users, both of how it works and of the problems it can cause. Her ReRAMs could replace the memory devices currently used in all types of smart electronics.

Chakraborty wishes to see her research become part of something bigger and hopes that, one day, we will all understand the carbon footprint that technology trends create. Technology trends move very quickly, and the waste generated as people discard one device for a newer one is becoming astronomical. Clearly, a monolayer of carbon atoms (graphene) is the smallest carbon footprint one can leave and still provide useful electronics, she says. Hopefully, her organic ReRAMs can combat some of the negative effects of our throwaway society.